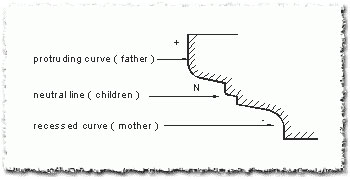

By sticking to the rules of the universe that contain ‘Yin’ and ‘Yang’ and the neutral line in line with the anthropic principle which laid on the basis of clear distinction between parents and their children, the old and the young ( Ref. Illustration 1). This is the principle that made the beauty of classic buildings everlasting.

To restore today’s architectural structures, we need to preserve its best while doing away with the gaudy aspect of the building. Based on the above principle, our construction method has specially designed a set of flexible fiberglass mould to suit your ever demanding needs. Concrete panels produced by using this method can easily meet the standards set by either architects or the house owners themselves.

The concrete panels can be tailored to meet any size or into any design as demanded by the architect. The structure of these panels is simple as it has only one standard vertical and one standard horizontal joint. This has enabled the structure to achieve refinement, while maintaining its simplicity and unparalleled quality; in other words, quality control that normally is dependent on man, is now monitored by the system. This construction method has been patented in the following countries: Malaysia, US, China, Australia, New Zealand, Egypt, South Africa, India, Taiwan, Brazil and Vietnam, while patent rights are pending in other countries as well.

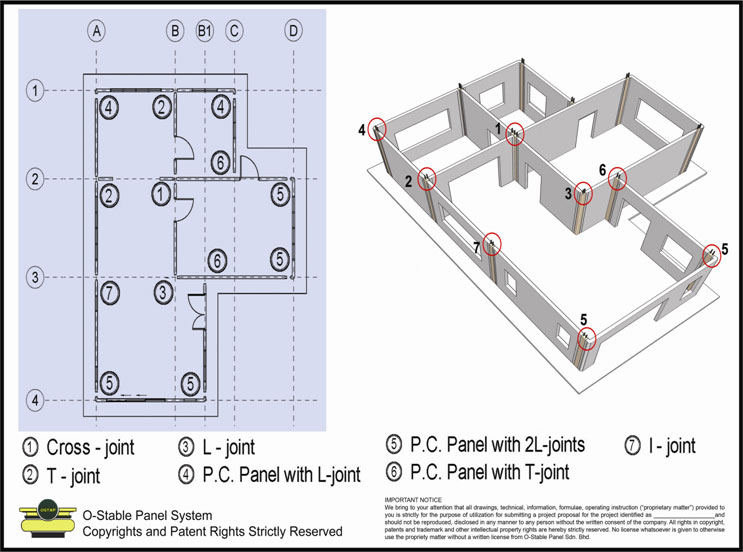

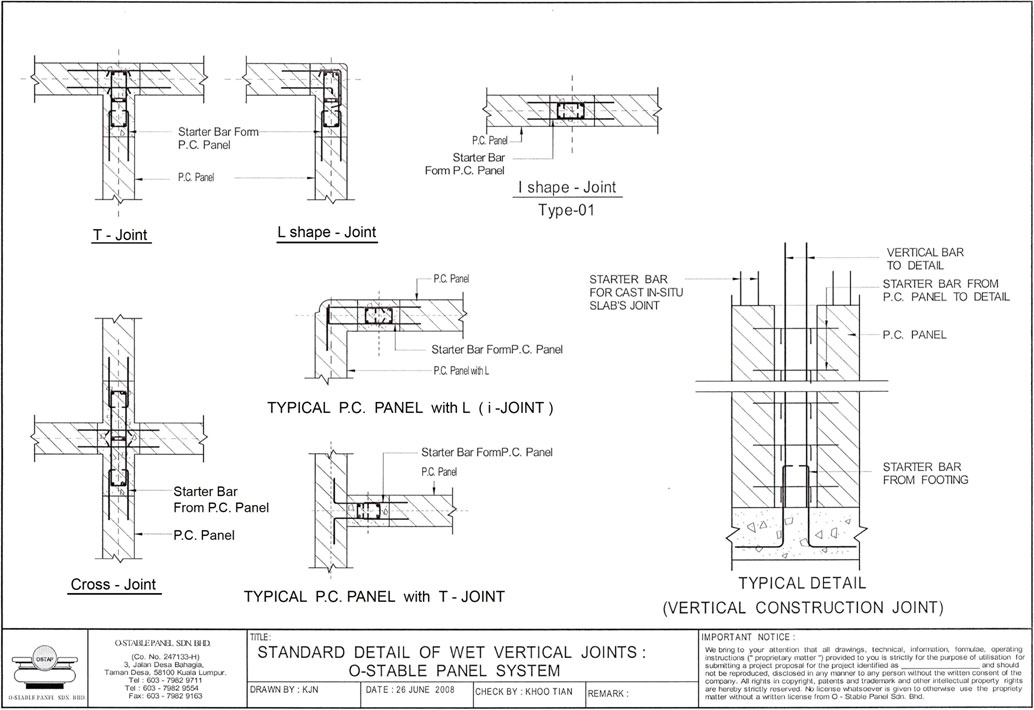

Vertical Construction Joints

The pre-cast wall with longitudinal recess at the edge to retain all leakage of cement slur arising from casting of in-situ concrete Vertical Joint. The pre-cast wall panels is aligned in a respective position at a distance apart to form the vertical concrete joints such as cross joint, T joint, L joint, Panel with L joint, Panel with 2 L joint, Panel with T joint and I joint , in which to provide a working space for a worker to tighten the starter bar from the pre-cast wall panels and vertical bar from foundation, and to accommodate tolerance dimension of the pre-cast wall panels.

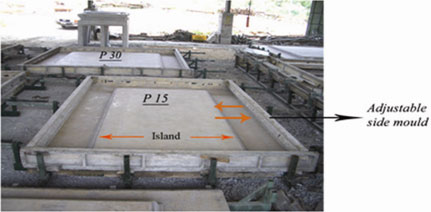

Mould Preparation And Casting

- Set the mould dimension accoring to casting plan.

- Tighten the side moulds.

- Apply mould oil to its base and side moulds.

- Laying wire-meshed and steel bars according to shop drawing.

- Laying electrical conduits according to Panel's M & E drawing.

- Pour concrete into the mould and make it flushed to the side moulds.

- If there is any water piping, using a template in the panel to form a channel for conceal piping.

- Next day, lift up the panel and store it into the stock pipe frame.

P10 : The width of "island" is 1000 mm

P15 : The width of "island" is 1500 mm

P30 : The width of "island" is 3000 mm

P35 : The width of "island" is 3500 mm